Release time:2024-08-01

Injection moldingIf the production link is not careful, it will cause various losses, which requires the injection molding factory to control each processing procedure and have a perfect processing system. Through more than 10 years of injection molding processing experience, the injection molding factory has formed a perfect processing process, and summed up the ten wastes in the injection molding process, efficient production and cost saving.

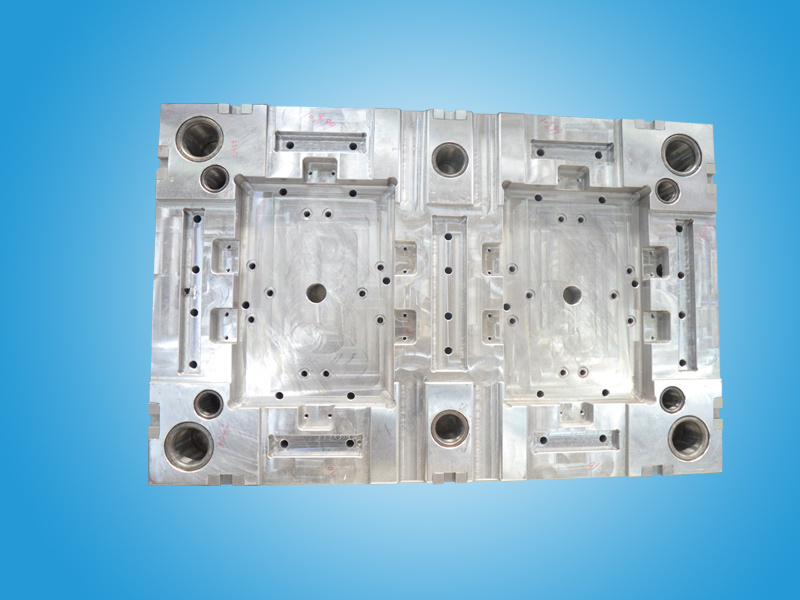

(1) The structure design of the injection mold is unreasonable, which leads to multiple mold trials and mold changes, and large consumption of raw materials, electricity and labor;

(2) Burr produced by injection molding parts, large amount of post-processing and large labor loss;

(3) The awareness of using, repairing and maintaining injection molds is not strong, and there are many mold failures or even damages in the process of injection molding, which often leads to a waste of mold repair downtime;

(4) The use, repair and maintenance of the injection molding machine are not in place, which shortens the service life of the injection molding machine and wastes caused by the shutdown and repair of the machine;

(5) The personnel allocation in the injection molding workshop is unreasonable, the division of labor is not clear, the responsibilities are not clear, and no one is responsible, resulting in the injection molding process and production is not smooth, resulting in waste;

(6) The vocational skills training is not enough, and the working ability and quality of the employees are poor. Many problems will lead to waste;

(7) The management concept is backward, cannot keep pace with the times, does not learn, does not progress, and the injection molding process management level is low, resulting in low production efficiency of the injection molding process;

(8) The injection molding process control is not in place, the production waste is large, and the defective rate is high, resulting in the waste of batch return;

(9) The raw materials used in the process of mold test and injection molding exceed the plan, and the nozzle materials or rubber heads at the machine position are not strictly controlled, resulting in a large loss of plastic raw materials;

(10) Improper planning or mold arrangement in injection molding production, frequent mold change or machine change, resulting in "material", "labor" and "cost" losses.